The Ultimate Guide To Caster Manufacturer

Wiki Article

The Best Guide To Caster Manufacturer

Table of Contents3 Easy Facts About Caster Manufacturer DescribedHow Caster Manufacturer can Save You Time, Stress, and Money.A Biased View of Caster ManufacturerA Biased View of Caster ManufacturerCaster Manufacturer for Dummies

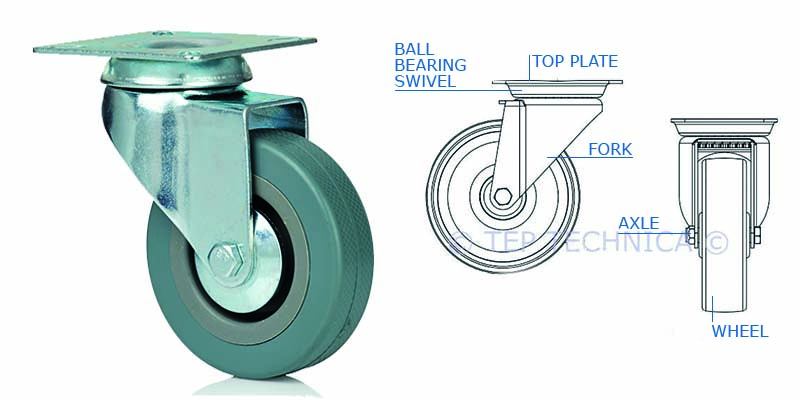

A basic, inflexible caster consists of a wheel installed to a fixed fork.

An instance of this is the wheels found at the rear of a buying cart in North America. Rigid casters have a tendency to limit vehicle motion so that the automobile follows a straight line. 2 wheeled swivel casters on a desk chair (no fork) Like the simpler rigid caster, a swivel caster integrates a wheel installed to a fork, however an additional swivel joint over the fork allows the fork to freely revolve concerning 360, thus allowing the wheel to roll in any type of instructions.

When the wheel is moved and also the wheel is not facing the proper instructions, the countered will certainly create the wheel setting up to revolve around the axis of the upright shaft to adhere to behind the instructions of movement. If there is no balanced out, the wheel will not rotate if not dealing with the correct instructions, either protecting against activity or dragging throughout the ground.

A consequence of this is that the automobile normally has a tendency to travel in a straight direction. Exact steering is not required since the casters often tend to keep straight motion.

Getting My Caster Manufacturer To Work

The caster rotates vertical to the turning distance as well as gives a smooth turn. This can be seen on a buying cart as the front wheels revolve at different rates, with various turning distance depending on exactly how limited a turn is made. The angle of, as well as range in between the wheel axles as well as swivel joint can be readjusted for various sorts of wheel performance.Industrial casters are strong casters that are created to carry hefty lots, sometimes up to thirty thousand pounds. An Industrial caster may have either a swivel or inflexible caster style. Industrial wheels generally have a flat leading plate that has four bolt holes to make sure a tough link between the top plate as well as the tons.

An extra complicated kind of swivel caster, often called an overall lock wheel, has an additional rotational lock on the vertical shaft so that neither shaft rotating nor wheel turning can occur, thus giving extremely inflexible support. It is possible to make use of these two locks together or individually. If the vertical shaft is locked but the wheel can still transform, the wheel becomes a directional caster, yet one which might be secured to roll in one direction along any kind of straight axis.

This system has no authority, hence the name kingpinless. The lack of an authority removes most root causes of swivel caster failure [] as well as minimizes or gets rid of shimmy after use [] They use capability and durability similar to systems having actually sealed precision sphere or conical bearings [], as well as are a functional option to typical swivel casters in high-impact scenarios []

The 5-Minute Rule for Caster Manufacturer

A common example of wheel flutter is on a supermarket buying cart, when one caster swiftly swings side-to-side. This oscillation, look at this site which is also referred to as shimmy, occurs normally at certain speeds, and also resembles speed up wobble that takes place in other rolled vehicles. The speed at which wheel flutter occurs is based upon the weight borne by her explanation the wheel and also the distance between the wheel axle as well as guiding axis.Usually, flutter occurs at broadband. What makes flutter unsafe is that it can cause a lorry to all of a sudden relocate an undesirable direction. Flutter occurs when the caster is not completely contact with the ground as well as therefore its alignment is uncontrollable. As the caster gains back full contact with the ground, it can be in any type of orientation.

At slower rates, the caster's capacity to pivot can correct the instructions and also can proceed travel in the preferred instructions. But at high speeds this can be hazardous as the wheel might not have the ability to swivel promptly enough and the automobile might stumble in any kind of instructions. Electric and also racing mobility device designers are really interested in flutter since the chair must be risk-free for motorcyclists.

Anytime the caster starts to tremble, it slows the chair and shifts weight to the front wheels. Other read the full info here techniques of decreasing caster flutter consist of increasing swivel lead, making use of heavier grease, minimizing the mass of the wheel, or increasing friction with the ground by transforming products.

The Best Strategy To Use For Caster Manufacturer

Ergonomic casters are made with consideration for the operating atmosphere as well as the task to be done to make sure that any kind of adverse effects on the operator are reduced. Long-term repetitive actions including standing up to casters can add to stress injuries. Incorrect requirements can additionally add to decreased service life of casters. Many criteria contribute in just how well the wheel carries out.Big size caster wheels are able to connect voids like that between the floor and also an elevator car. Nevertheless, the larger the size of a caster wheel, the greater the wheel support arm need to be. Either the base of a low-hanging things should be lifted greater above the wheels, or the casters should hang out to the sides straddling the low-hanging sustained things.

Larger wheels call for more of this space. Lots capacity may be enhanced by making use of larger wheels with even more ground get in touch with location. When turning a large swivel wheel in-place, the center component of the wheel-to-ground call patch revolves slower than the regions additionally out to the sides. This difference in turning rate across the base of the wheel contact patch triggers wide wheels to stand up to turning around the swivel, as well as this resistance increases as weight loading rises.

Each wheel has a comparatively narrower ground get in touch with spot than a single vast wheel, so there is much less resistance to transforming in position on the swivel. There are 4 primary classifications of wheels: A common wheel has a center revolving center (or bearing) as well as a certified material on its outer side.

More About Caster Manufacturer

An omnidirectional wheel (Mecanum wheel, Omni wheel, or Swedish wheel) is made from a big central center with lots of additional smaller wheels placed along the perimeter such that their axes are perpendicular to the central wheel. The central wheel can turn around its axis like conventional wheels, but the smaller sized wheels can additionally allow motion vertical to the central axis.

An instance is a ball transfer device (Caster Manufacturer).

Report this wiki page